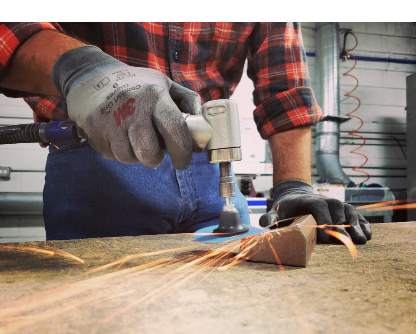

Equipped with stroke sanders, wide belt sanders, tube polisher, polishing lathes and a multitude of hand tools we can always find a solution for your job.

This is a ground unidirectional finish obtained with a 150 grit abrasive. It is not highly relfective, but is a general purpose finish on components which will suffer fairly rough handling in service (e.g. restuarant equipment).

NO. 3 FINISH

This is a ground unidirectional uniform finish. Obtained with 80-100 grit abrasives. The end result gives it a non-reflective, general purpose finish.

NO. 6 FINISH

NO. 7 FINISH

This is a buffed finish having a high degree of reflectiveness. It is produced by progressively using finer and finer abrasives then finishing with buffing compounds. Some fine stratches (grit lines) may remain from the original starting surface.

NO. 8 FINISH

Similar to a No. 7 finish, the final operation is done with extremely fine buffing compounds. The final surface is blemish free with a high degree of image clarity and is a true mirror finish.

NO. 4 FINISH

Our Capabilities:

- Sheets & Panels

- Extrusions

- Tube Stock - Up to 20'

- Bar Stock - Up to 20'

- Metal Spinnings

- Chassis

- Endless Other Configurations

These finishes are produced using rotating cloth mops, which are loaded with abrasive paste. The finish depends on how fine of an abrasive is used. The finish has a unidirectional texture of varying reflectiveness.

ALWAYS FINISH STRONG

Add Text Here...